ALPHA

$14,492.00

| Duty Rating | Extreme-Duty |

|---|---|

| Cutting Width | 72" |

| Hydraulic Flow Range | 23-45 GPM |

| Max Cutting Diameter | up to 10" |

| Motor Style | Direct-drive radial piston motor |

* The manufacturer’s suggested retail price (MSRP) does not include shipping and taxes. Dealers set actual prices, including invoicing currency.

Description

Dare we say the “The Beast” of all cutters? This fierce cutting machine is not for the faint-hearted. We beefed up the direct-drive piston motor and paired it with a massive 3.25” shaft diameter bearing housing for extreme cutting power. The unique “v-notch” design delivers a closer cut and operator precision when leveling trees and saplings. And by trees, we mean 10” thick trees. We then demanded the most robust blade carrier system on the market (there are two to choose from), so you’ll get the performance and power to master the toughest, most demanding jobs.

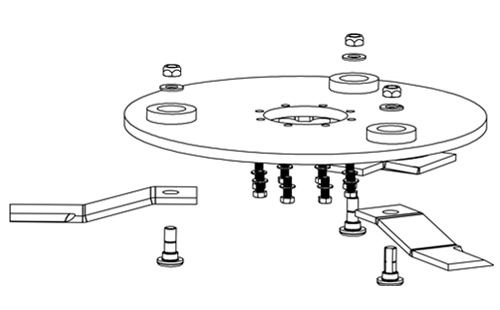

3-Blade Carrier

STANDARD

Number of Blades

3

Blade Type

High-tempered non-updraft drop blades.

Blade Carrier

1” GRD-50 disc.

All Brush Wolf blade carriers are CNC balanced for ultra-smooth operation.

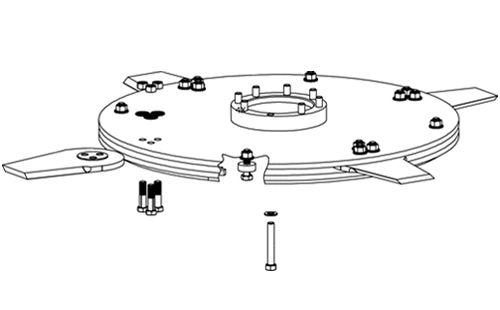

4-Blade Carrier

OPTIONAL

Number of Blades

4

Blade Type

Hardox® 500 flat blades; non-updraft.

Blade Carrier

Two-piece 5/8" steel disc propriety blade system exclusive to Brush Wolf. Blades are secured between two 5/8” thick high-strength steel discs.

All Brush Wolf blade carriers are CNC balanced for ultra-smooth operation.

Long-Lasting Blades

The Brush Wolf industrial-strength blades are heat treated, have a milled edge, and are Supertuf coated to stand the test of time.

Direct-Drive Piston Motor

Experience the power of the direct-drive SAI® radial piston motor. With higher torque, you’ll get more cutting power, quicker recovery time, and less bogging down when accelerating through thick brush.

Massive Bearing Housing

We pair our direct-drive radial piston motor with a robust Eskridge® bearing housing that has a 3.25” shaft diameter and patented shaft retention system.

Motor Protection

Pressure Relief Valves: Added pressure relief valves safeguard your motor from pressure spikes and allow for a faster shutdown.

Case Drain is included to relieve excess pressure build-up and protect the motor.

Gearbox Seal Protection

A welded seal guard collar prevents wire, twine, and vegetation from wrapping around and damaging the gearbox.

Ultra-Rugged Deck Frame

Here’s why our brush cutters last for life. We build each deck frame from a single piece of formed 1/4" thick heavy-duty steel, never pieced together. This means our frames are consistently better made and more durable, with the elimination of construction errors and frame failure. One-piece frames will always provide superior strength.

Clean Deck Design

Our one-piece deck frame construction creates a “clean deck” design that allows material to glide off, preventing unwanted debris buildup. (Think less mess and easier to clean.)

Seam Welding

Unlike our competitors, Brush Wolf’s deck and frame construction is fully boxed and continuously welded across each seam for an indestructible, rust-proof support structure.

Reinforced Gussets

We went above and beyond to make sure our cutters are crazy strong by adding boxed-in gusset reinforcements, extra bracing, and supports.

Powder-Coated Tough

Protected with the most durable finishing process, we powder coat every part to minimize rust, resist scratches, and prevent fading, so you get more life out of your brush cutter.

Push Bar

Massive, fully-supported serrated push bar with teeth to bite into anything in its way.

Blade Access Cover

Easy access to the blade bolts for quick blade replacement.

Plug + Play Ready

Everything is ready to go upon delivery with the included quick-connect couplers, 114" hydraulic hoses encased in protective wrap, and dust caps to prevent line contamination.

Advanced Hose Routing System

We took the time to devise a well-thought-out hose routing system based on real-life situations. Using guides and STAUFF clamps, our hydraulic lines can be routed to either side. So, you choose which side works best for your machine.

Protected Hydraulic Hoses

Our ALPHA hydraulic hoses are guarded with extreme-duty spiral hose wrap to stave off entanglements from branches and keep you cutting.

Hood

The vented hood fully encloses the motor and drive components to shield them from damaging impacts and debris.

Deflector Plate

We upped the safety by adding a deflector plate to control the discharged material coming out of the front of the deck to protect both people and nearby structures.

Safety Steps

Enhancing safety is our thing, so we added two non-slip, serrated metal steps for easy in and out.

Universal Quick Attach System

Time is money, so we made sure our cutters attach quickly to your machine by using the industry-standard Quick Attach system. It will only take seconds to attach/detach your machine with our universal pick-up plate.

Choose Your Color

Black, yellow, or make it your own custom color.

Parts Always Available

Brush Wolf only uses well-known industry-leading parts and components that are—and will always be—available to order 24/7 at www.brushwolf.com/parts or by calling 877-390-9857.

| PSI cont./int. | 3,000/4,100 |

|---|---|

| Deck Thickness | 1/4 in |

| Motor/Gearbox Coupler | Machined steel |

| Motor Protection | Pressure relief valves, case drain |

| Blade Carrier (3 Drop Blade Carrier) --standard-- | 1” GRD-50 disc |

| Blade Carrier (4 Flat Blade Carrier) --optional-- | Two-piece 5/8" steel discs |

| Blade Rotation | Counterclockwise |

| (3) Drop Blades --standard-- | 18 x 5 x 0.625 in; non-updraft |

| (4) Hardox® 500 Flat Blades --optional-- | 18 x 8.5 x 0.625 in; non-updraft |

| Hood | 12-ga hinged, motor guard |