Open Front / Heavy-Duty Series

$8,139.00

| Duty Rating | Heavy-Duty |

|---|---|

| Cutting Width | 66", 72", or 78" |

| Hydraulic Flow Range | 10-40 GPM |

| Max Cutting Diameter | up to 3", up to 4", up to 5" |

| Motor Style | Geroler-style hydraulic motor; right-angle gearbox |

* The manufacturer’s suggested retail price (MSRP) does not include shipping and taxes. Dealers set actual prices, including invoicing currency.

Description

Let’s turn grueling work into a walk in the park. Our open-front cutters thrive in harsh environments thanks to the exposed high-tempered steel blades that blast through brush up to 5″ thick. The unique open front design lets you selectively cut vegetation before deck contact and then discharge the debris quickly to accelerate your job completions. The field-proven combination of the easy-to-maintain hydraulic motor and 65HP right-angle gearbox speeds up the rotation to achieve the highest torque possible while maintaining a proven tip speed. These cutters will make quick work of your tough clearing jobs.

Number of Blades

(2) 0.5 x 4 in; non-updraft

Blade Type

High-tempered non-updraft steel blades to cut and discharge material quickly.

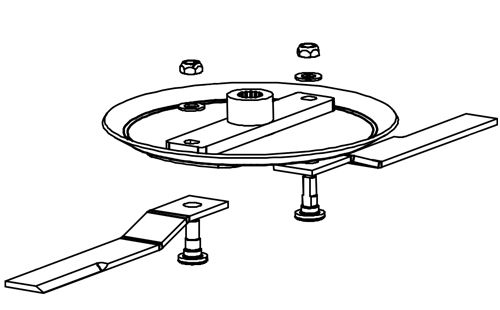

Blade Carrier

5/16" GRD-50 spun-formed pan.

All Brush Wolf blade carriers are CNC balanced for ultra-smooth operation.

Long-Lasting Blades

The Brush Wolf industrial-strength drop-down blades are heat treated, have a milled edge, and are Supertuf coated to stand the test of time.

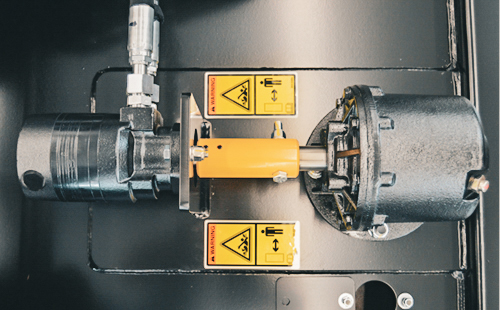

Premium Hydraulic Motor

We paired the top-of-the-line Eaton® Geroler-style hydraulic motor with the most dependable right-angle Omni® gearbox to achieve maximum torque and ideal blade tip speed. This easy-to-maintain and tried-and-true pairing will survive the years of abuse it will see in the field.

Motor Protection

Pressure Relief Valves: Added pressure relief valves safeguard your motor from pressure spikes and allow for a faster shutdown.

Grade-2 Shear Bolt: protects the gearbox and driveline from damage.

Gearbox Seal Protection

A welded seal guard collar prevents wire, twine, and vegetation from wrapping around and damaging the gearbox.

Ultra-Rugged Deck Frame

Here’s why our brush cutters last for life. We build each deck frame from a single piece of formed 1/4" thick heavy-duty steel, never pieced together. This means our frames are consistently better made and more durable, with the elimination of construction errors and frame failure. One-piece frames will always provide superior strength.

Clean Deck Design

Our one-piece deck frame construction creates a “clean deck” design that allows material to glide off, preventing unwanted debris buildup. (Think less mess and easier to clean.)

Seam Welding

Unlike our competitors, Brush Wolf’s deck and frame construction is fully boxed and continuously welded across each seam for an indestructible, rust-proof support structure.

Reinforced Gussets

We went above and beyond to make sure our cutters are crazy strong by adding boxed-in gusset reinforcements, extra bracing, and supports.

Powder-Coated Tough

Protected with the most durable finishing process, we powder coat every part to minimize rust, resist scratches, and prevent fading, so you get more life out of your brush cutter.

Push Bar

Let’s help “feed” the cutter with a welded push bar to knock down taller vegetation and trees and enhance the cutting capabilities.

Slotted Front Shield

Slotted front shield provides increased visibility while protecting the operator from debris.

Stump Jumper

These 5/16" spun-formed pans allow the cutter to glide over stumps, roots, and rocks that may dull, chip, or damage your blades.

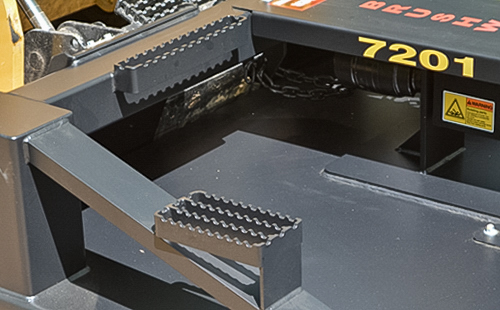

Blade Access Cover

Easy access to the blade bolts for quick blade replacement.

Plug + Play Ready

Everything is ready to go upon delivery with the included quick-connect couplers, 78" hydraulic hoses encased in protective wrap, and dust caps to prevent line contamination.

Chain Curtain

Chains hanging from the rear of the cutter prevent debris from being discharged.

Hood

12-gauge steel motor guard protects from damaging impacts. Hinged for easy motor access.

Lift Limit Chain

A lift limit chain has been added for your safety, which prevents the cutter from being lifting too high.

Safety Steps

Enhancing safety is our thing, so we added two non-slip, serrated metal steps for easy in and out.

Universal Quick Attach System

Time is money, so we made sure our cutters attach quickly to your machine by using the industry-standard Quick Attach system. It will only take seconds to attach/detach your machine with our universal pick-up plate.

Choose Your Color

Black, yellow, or make it your own custom color.

Parts Always Available

Brush Wolf only uses well-known industry-leading parts and components that are—and will always be—available to order 24/7 at www.brushwolf.com/parts or by calling 877-390-9857.

| PSI cont./int. | 3,000/3,500 |

|---|---|

| Deck Thickness | 1/4 in |

| Motor/Gearbox Coupler | Machined steel |

| Motor Protection | Pressure relief valves, GRD-2 shear bolt |

| Blade Carrier | 5/16" GRD-50 spun-formed pan |

| Blade Rotation | Counterclockwise |

| Blades | (2) 0.5 x 4 in; non-updraft |

| Hood | 12-ga hinged, motor guard |